einfach mehr

OF SALE VON

MORGEN

Unsere Produktionspartner in Asien gehören zu den führenden Unternehmen der Branche und verfügen über eine SA 8000 Zertifizierung, welche faire Arbeitsbedingungen für die Mitarbeiter sicherstellt.

OF SALE VON

MORGEN

Bei Produktionen in der Schweiz setzen wir so weit wie möglich auf soziales Engagement und arbeiten seit Jahren intensiv mit geschützten Werkstätten zusammen. Das hat gleich zwei Vorteile; es gibt benachteiligten Menschen eine sinnvolle Beschäftigung und hält die Produktionskosten tief.

Unsere Produktionspartner in Asien gehören zu den führenden Unternehmen der Branche und verfügen über eine SA 8000 Zertifizierung, welche faire Arbeitsbedingungen für die Mitarbeiter sicherstellt.

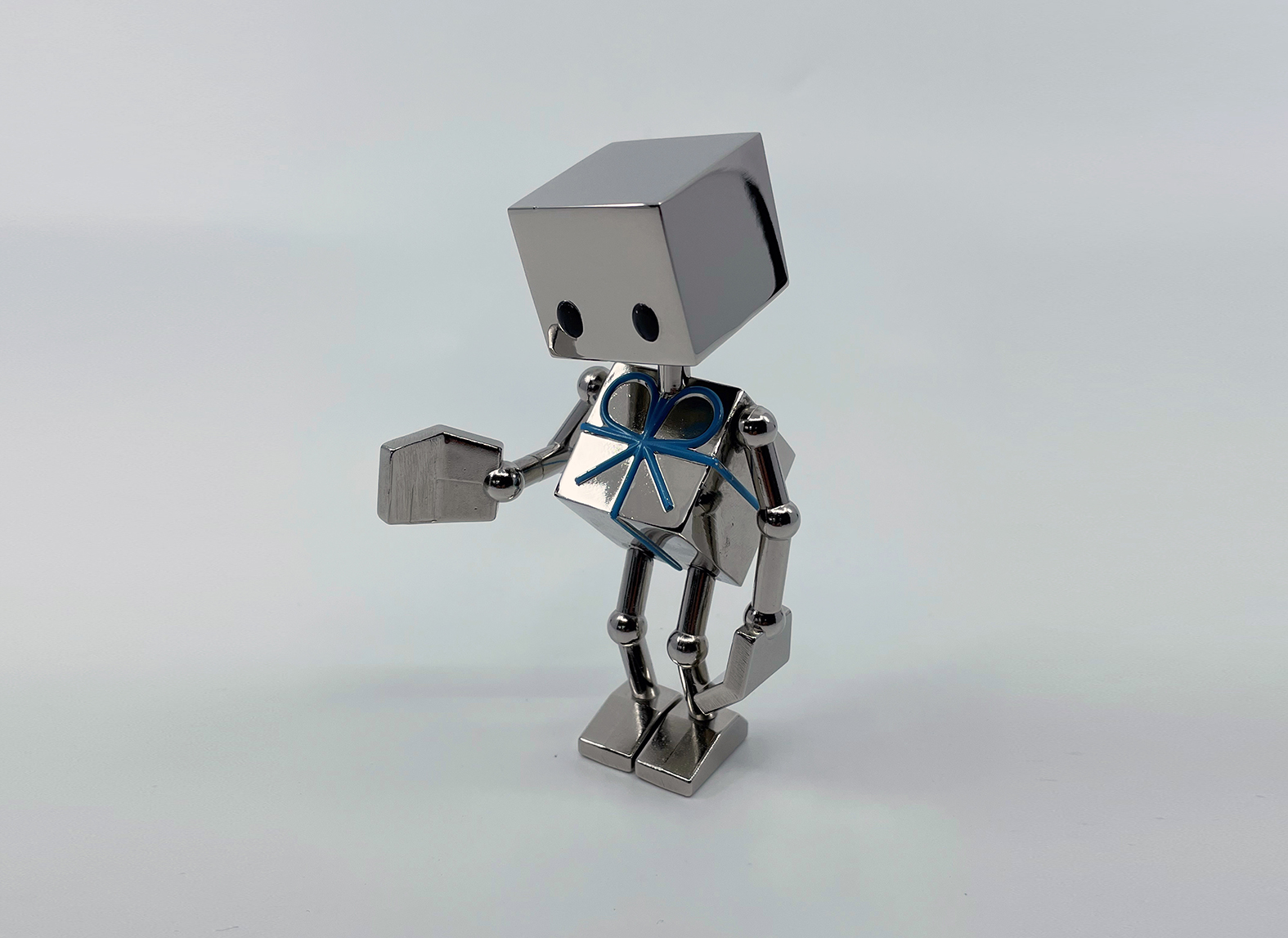

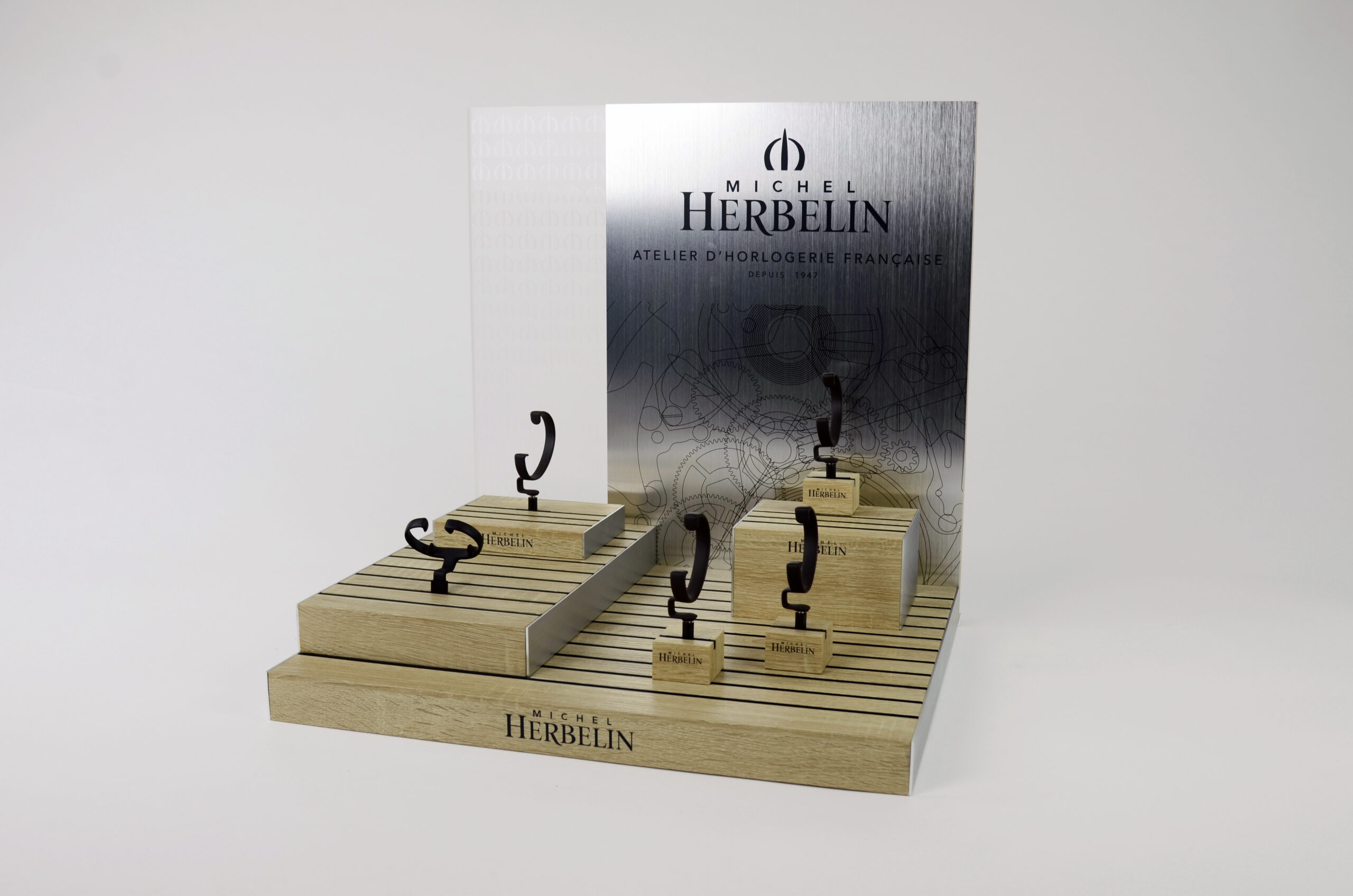

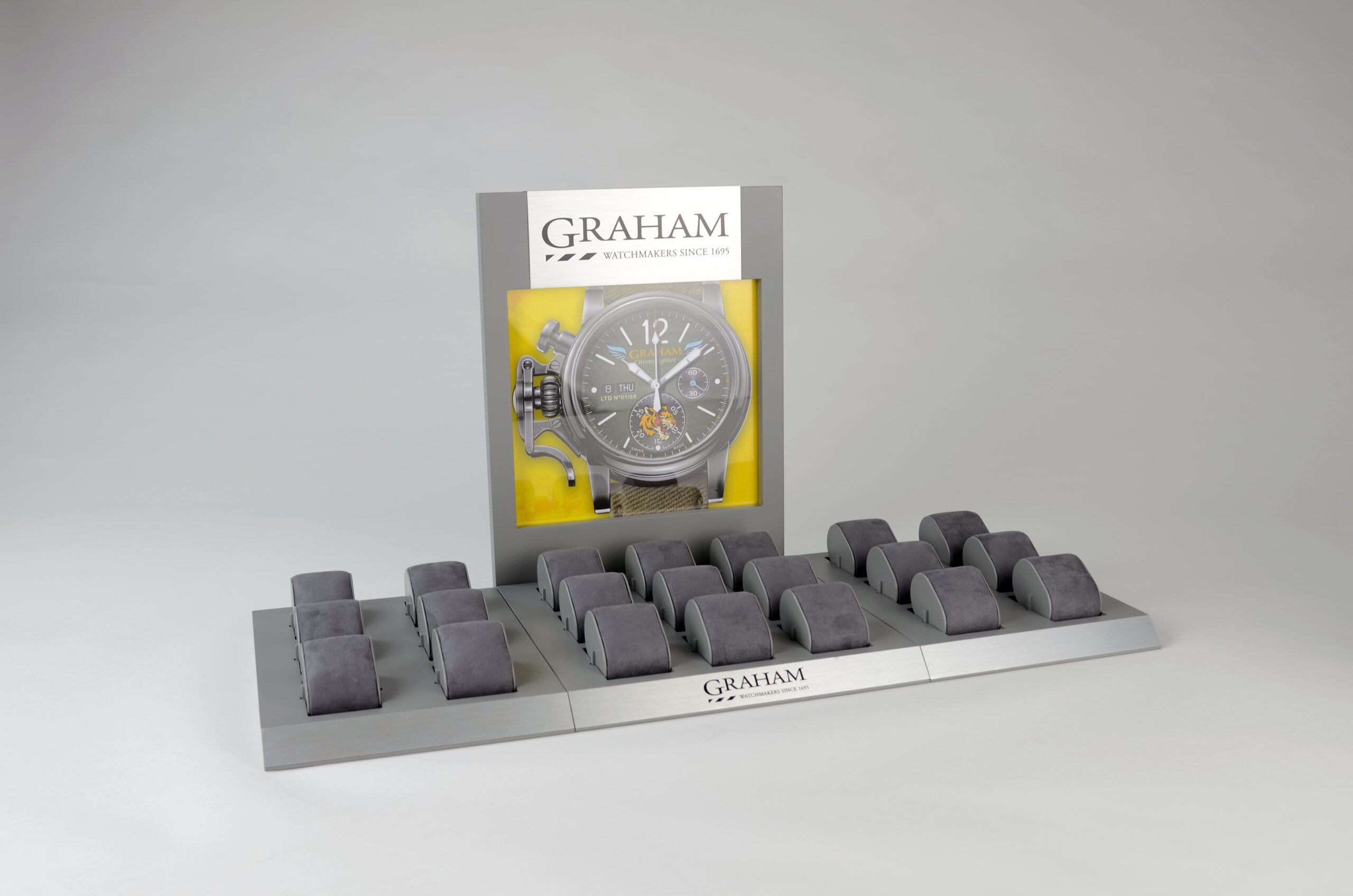

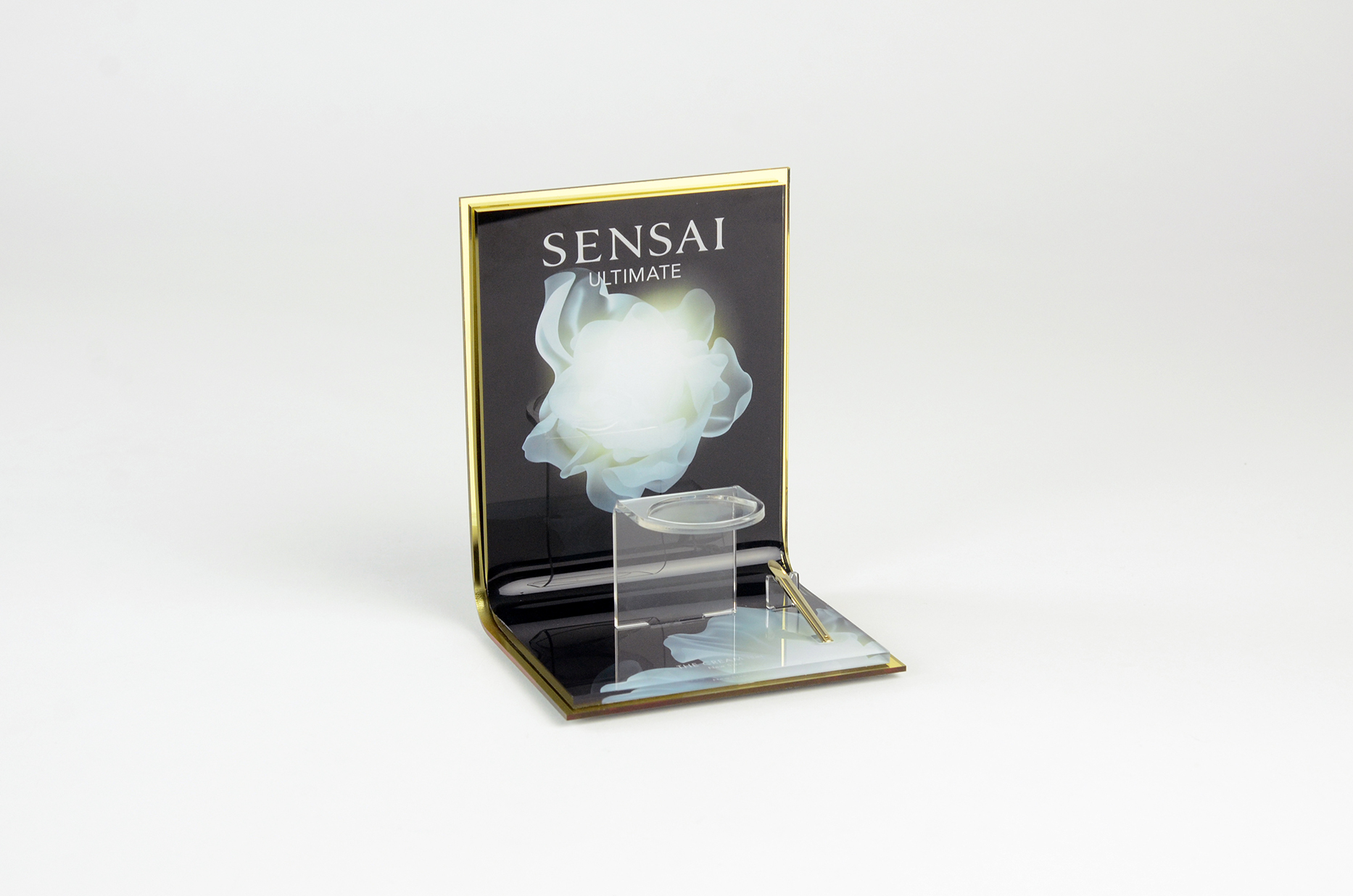

UND DESIGN

Wir arbeiten mit Ihren Corporate-Materialien oder suchen diese für Sie aus. Neben den traditionellen Displaylösungen bieten wir auch moderne Lösungen mit integrierter Elektronik an. Die Designentwürfe werden von uns erstellt oder das bereits vorhandene Design direkt von Ihnen übernommen.

Wir fertigen unsere Displays aus Metall, Holz und/oder Kunststoff an. Dabei werden die Materialien bei jedem Prozess einer ständigen Kontrolle unterzogen. Somit kreieren wir Displays, die Ihre Botschaft nicht nur perfekt transportieren, sondern darüber hinaus auch qualitativ überzeugen.

UND DESIGN

Wir arbeiten mit Ihren Corporate-Materialien oder suchen diese für Sie aus. Neben den traditionellen Displaylösungen bieten wir auch moderne Lösungen mit integrierter Elektronik an. Die Designentwürfe werden von uns erstellt oder das bereits vorhandene Design direkt von Ihnen übernommen.

Unsere Displays stellen wir für Sie individuell her und achten dabei auf eine nachhaltige Produktion sowohl bei den Displays als auch bei den Verpackungen. Alle verwendeten Materialien erfüllen höchste Qualitätsstandards.

Wir fertigen unsere Displays aus Metall, Holz und/oder Kunststoff an. Dabei werden die Materialien bei jedem Prozess einer ständigen Kontrolle unterzogen. Somit kreieren wir Displays, die Ihre Botschaft nicht nur perfekt transportieren, sondern darüber hinaus auch qualitativ überzeugen.

GESCHÄTZT